Double Disc Pump™ vs. Diaphragm Pump

True Double Disc Pump Technology

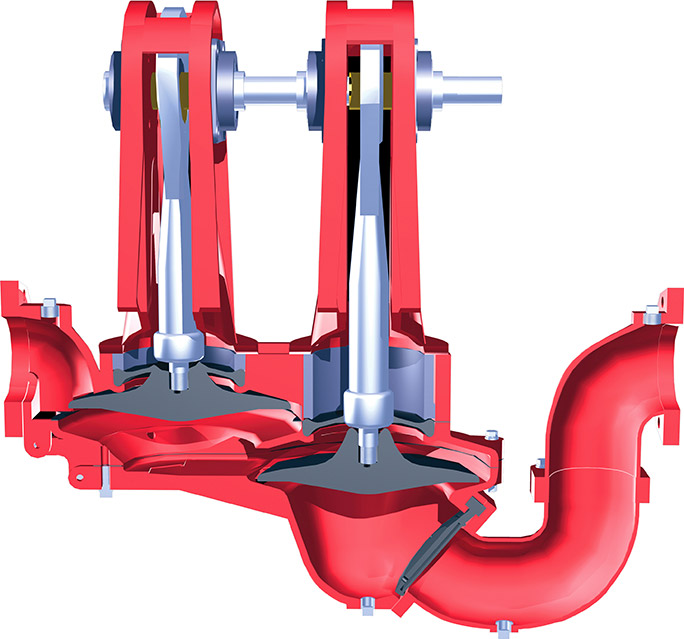

True double disc pump technology is based on a ‘non-captive’ free disc design where two discs are staged in the pump housing.

These discs work in unison to perform the duties of both the pumping element and valving element. The hydraulic interaction between the discs creates vacuum and pressure simultaneously to move fluid from suction to discharge. Since the discs are not captive in the housing, they are not subject to the flex fatigue failure pattern associated with captive diaphragm pump designs. The discs are an integral elastomer design with rigid core and do not have any external metal components.

The double disc pump has a short stroke length created by eccentric cams pinned to the drive shaft. The pump design provides for positive valving on every stroke since the discs are mechanically driven on the seat. The pump incorporates an inlet side foot valve, also known as a clack valve. This device is a priming and re-priming aid and only sees action under a suction lift condition or when the suction line is under a vacuum condition. In flooded suction applications, this device does not get back to the seating surface and does not valve. The pump will operate without the clack valve on flooded suction applications. This unique design allows the pump to pass larger solids, rags and debris that would routinely cause problems like clogging and failure on other types of pumps internal check valves.

Diaphragm Pump Technology

Diaphragm pump technology incorporates one ‘captive’ diaphragm that is ‘sandwiched’ between the pump housing and retaining mechanism. Each diaphragm pump is a simplex unit that contains one diaphragm and two ball check valves. A duplex diaphragm pump adds another simplex pump in parallel and then drives it with a common motor. A triplex pump adds a third, and so on in order to accomplish higher flow rates. The center of the diaphragm is mechanically attached to a connecting rod that raises and lowers the diaphragm on every revolution. The stroke length is large and leads to a flexing the diaphragm twice – upstroke and down stroke- per revolution. This design also requires the use of internal check valves, like a ball or flapper, for operation. Without these check valves the pump will not operate.

The weakness in using diaphragm pump technology is found in the flex fatigue life of the diaphragm and the clogging of the ball check valves.

The check valves rely on gravity to get back to the seating surface. When debris gets trapped between the ball valve and seat, the unit stops pumping. The reason these designs have a quick release cap to access the ball valve is that clogging is a frequent occurrence and requires the check valve to be accessed and the debris removed so the pump can be made operational again.

The typical operating life between rebuilds for a double disc pump is thousands of hours since the discs are not captive and therefore not subject to flex fatigue failure. Industry feedback on the diaphragm pump technology is that the lifespan of the diaphragm only lasts in the hundreds of hours given the flexing action of the diaphragm. This is a significant difference in the pump technologies and therefore the reliability and long-term operational costs between a double disc pump and diaphragm pump.

A Diaphragm Pump Is Not A Double Disc Pump

Competitors have manufactured diaphragm pump technology for many years and have properly called it such. It has only been used as a contractor’s pump in relatively light duty applications because of its limited run hours between diaphragm failure and low head limitations.

In recent years, competitors have begun marketing some of their pumps as double disc pumps by modifying the bearing pedestal design so externally it looks like a double disc pump, when in reality it is still a diaphragm pump. The diaphragm in these types of pumps has been renamed a ‘trunnion’, which is an external metal plate that attaches a connecting rod to the diaphragm – or what is erroneously being called a ‘disc’.

PUMP COMPARISON: Double Disc Pump vs. Mechanical Diaphragm Pump

| Features | Double Disc Pump | Diaphragm Pump |

|---|---|---|

| Technology | True double disc pump technology is based on a ‘non-captive’ free-floating disc design where two independent discs perform duties of both pump and valve. Short stroke length is not subject to flex fatigue failure and operates into thousands of hours between rebuilds. | A traditional single ‘captive’ diaphragm technology requires internal check valves for operation. Long stroke length and captive diaphragm leads to flex fatigue failures in the hundreds of hours. |

| Discs | Integral (no external metal components) reinforced elastomeric component that is both the pumping and valving element. | Competitor’s disc is created using external metal plates that sandwiches the diaphragm from above and below. |

| Trunnion | The sealing device in a true double disc technology is molded to flex only when in the downward stroke, extending flex life. Provides no pumping action. It only has a 9” diameter on largest model and is reinforced to eliminate catastrophic failure. | The diaphragm in the competitor’s model has been renamed a trunnion based on PVP terminology. This is a captive device that is 14”in diameter and flexes on both upward and downward stroke leading to twice the flexure rate and therefore shorter life. |

| Drive Arrangement | Inexpensive to replace, simple V-belt and pulley drive system. | Expensive to replace mechanical gear-motor arrangement that is close coupled to drive shaft. |

| Pump Drive Assembly | Short stroke length cam arrangement. Utilizes non-corrosive lightweight aluminum modular pedestals and connecting rods. Eccentric cams are cast bronze-alloy and pinned to shaft with Spirol® drive pins that absorb reciprocating load of pump. | Long-stroke cam arrangement. Utilizes ductile iron pedestals, connecting rods and eccentric cams which rust and corrode. Cams are keyed to shaft with traditional keyway and setscrew arrangement which is inferior for reciprocating loads. |

| Internal Check Valves | A double disc pump does not have internal check valves. The inlet clack valve is a priming device that only operates under suction lift and high vacuum installation. Pump works without this device on flooded suction applications. | Pump will not operate without the 5-1/4” ball check valves or flapper check valves on suction and discharge side. These items rely on gravity to get back to seat. If there is debris on seat, the pumping stops. |

| Pumping Action | Short stroke length produces small pulses and relatively smooth flows. | Long stroke length produces large pulses and large pressure spikes in flow. |

| Maintenance | Maintain-in-Place design with integral hinged housings. Allows pump to be serviced without removing pump from mounting frame or disturbing piping. Staged assembly allows for disassembly one section at a time. | Pedestal assembly requires complete removal when diaphragm fails. On multiplex units all pedestals have to be removed even when only one diaphragm fails. Ball check valves clog often, requiring frequent clean out. |

| Base Frame and Covers | Standard in SS304 | Carbon steel, painted. Pumps must be mounted on elevated concrete foundation that is the owner’s or contractor’s responsibility. |

| Pump Configurations | Units are simplex design with single motor. Provides easier maintenance. | Duplex, triplex and quadraplex units are large footprint with multiple pumps manifolded together and driven by single motor. |