American-Made

in Positive

Displacement

Pumps

& Food Processing Industries

- Maintain in Place™

- Runs Dry Without Damage

- Seal-less Design

- No Routine Maintenance Required

- Handles Viscous + Abrasive Materials

Available in 7 sizes with accessories.

The Ultimate in Positive Displacement Pumps for the Municipal, Industrial, Chemical and Food Processing Industries

Who We Are

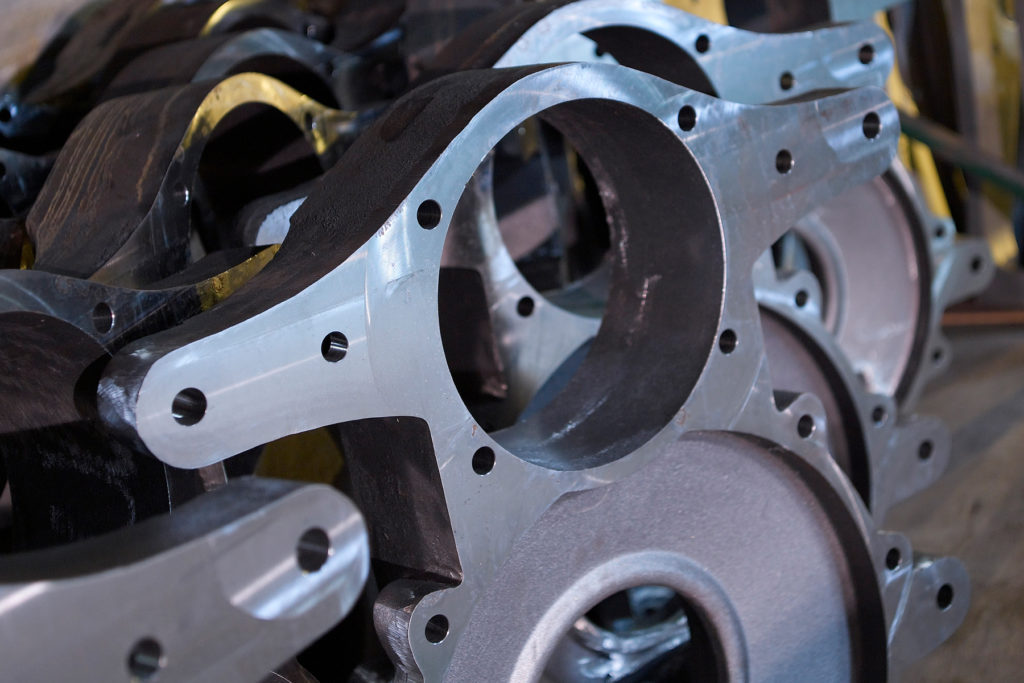

Since 1980, Penn Valley Pump has been developing and manufacturing the Double Disc Pump™ for use in the municipal, industrial and chemical industries.

Our Operating Principle

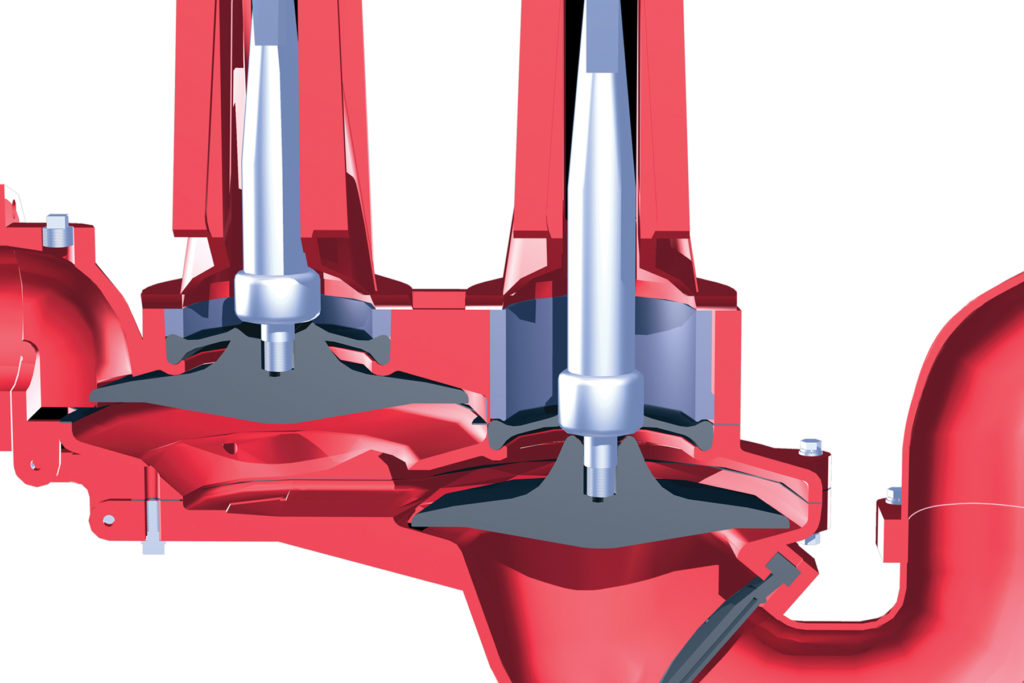

PVP’s Double Disc Pump™ combines the performance features of a positive displacement pump and the principle of ‘induced flow’ to provide superior versatility in fluids handling.

Our Products

PVP offers seven different Double Disc Pump™ sizes that are based on ‘induced flow’, that allows for superior versatility in fluid handling.

Less is More

Less wear equals longer life. Our double disc pumps run up to 10 times longer with up to 70% less maintenance than rotary positive displacement pumps. Thanks to the ‘non-captive’ free disc design of our double disc pumps, friction is minimized, repairs are reduced and clogs are almost non-existent.